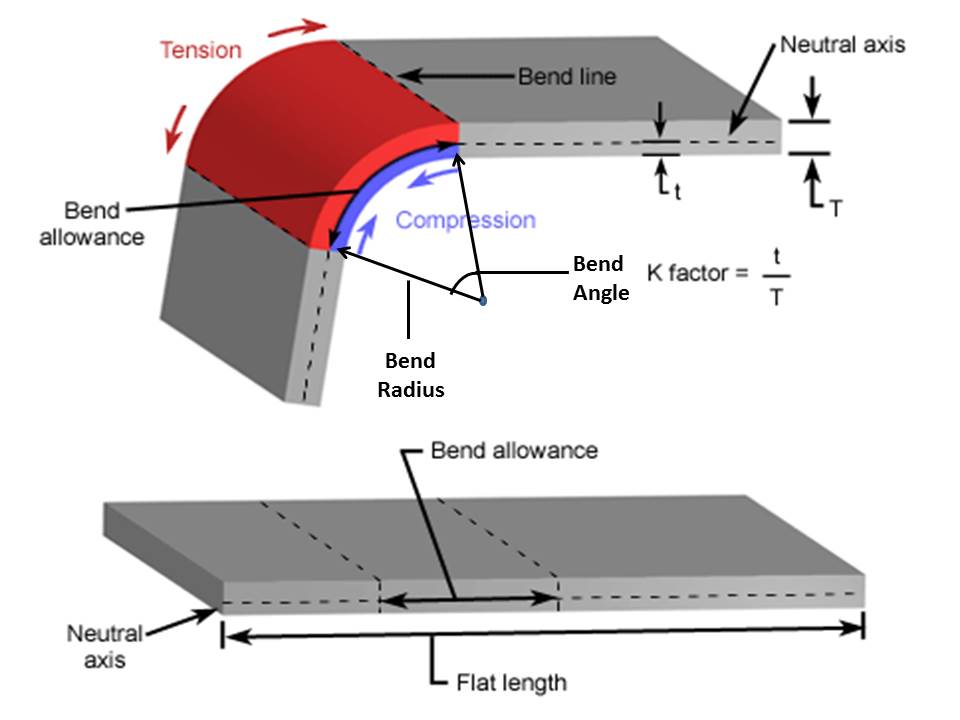

Sheet Metal Bend Tips . in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they have in industries ranging from automotive to aerospace. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. — sheet metal design tips for bending. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. — imagine bending sheet metal without leaving a single mark or scratch. — how to design bend reliefs & corner reliefs for sheet metal parts. sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle.

from www.mech4study.com

— imagine bending sheet metal without leaving a single mark or scratch. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. — sheet metal design tips for bending. — how to design bend reliefs & corner reliefs for sheet metal parts. sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle. in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they have in industries ranging from automotive to aerospace. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness.

Different Sheet Metal Bending Process mech4study

Sheet Metal Bend Tips — sheet metal design tips for bending. sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they have in industries ranging from automotive to aerospace. — sheet metal design tips for bending. — how to design bend reliefs & corner reliefs for sheet metal parts. — imagine bending sheet metal without leaving a single mark or scratch.

From www.shenchong.com

Sheet Metal Bending Design Guidelines Sheet Metal Bend Tips the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. — imagine bending sheet metal without leaving a single mark or scratch. . Sheet Metal Bend Tips.

From an-prototype.com

The Ultimate Guide to Sheet Metal Bending ANPrototype Sheet Metal Bend Tips the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. — sheet metal design tips for bending. in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they. Sheet Metal Bend Tips.

From fractory.com

Sheet Metal Bending Design Tips, Bend Allowance, K Factor Fractory Sheet Metal Bend Tips Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they have in industries ranging from automotive to aerospace. — imagine bending sheet metal. Sheet Metal Bend Tips.

From www.mech4study.com

Different Sheet Metal Bending Process mech4study Sheet Metal Bend Tips — imagine bending sheet metal without leaving a single mark or scratch. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle. . Sheet Metal Bend Tips.

From xometry.eu

Minimum Bend Radius Reference Table For Sheet Metal Xometry Europe Sheet Metal Bend Tips sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle. — sheet metal design tips for bending. — imagine bending sheet metal without leaving a single mark or scratch. the basic bending design guidelines that a designer needs to consider when. Sheet Metal Bend Tips.

From www.3erp.com

Sheet metal bending Sheet Metal Bend Tips — sheet metal design tips for bending. — imagine bending sheet metal without leaving a single mark or scratch. in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they have in industries ranging from automotive to aerospace. — how to design. Sheet Metal Bend Tips.

From www.youtube.com

Mastering Sheet Metal Bend Calculations in Onshape Tech Tip YouTube Sheet Metal Bend Tips in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they have in industries ranging from automotive to aerospace. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance.. Sheet Metal Bend Tips.

From ar.inspiredpencil.com

Sheet Metal Bending Techniques Sheet Metal Bend Tips sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle. — sheet metal design tips for bending. — imagine bending sheet metal without leaving a single mark or scratch. the basic bending design guidelines that a designer needs to consider when. Sheet Metal Bend Tips.

From fractory.com

Sheet Metal Bending Design Tips, Bend Allowance, K Factor Fractory Sheet Metal Bend Tips sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. — how to design bend reliefs & corner reliefs for sheet metal parts.. Sheet Metal Bend Tips.

From cncfirst.com

How To Bend Sheet Metal? cncfirst Sheet Metal Bend Tips sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle. — sheet metal design tips for bending. — imagine bending sheet metal without leaving a single mark or scratch. Sheet metal parts are usually fabricated from a single sheet of metal, so. Sheet Metal Bend Tips.

From makeitfrommetal.com

Tips for Bending Sheet Metal Make It From Metal Sheet Metal Bend Tips Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. sheet metal bending is a manufacturing process where a force is applied to. Sheet Metal Bend Tips.

From metalscut4u.com

How To Bend Sheet Metal The Ultimate Guide Sheet Metal Bend Tips — how to design bend reliefs & corner reliefs for sheet metal parts. in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they have in industries ranging from automotive to aerospace. sheet metal bending is a manufacturing process where a force is. Sheet Metal Bend Tips.

From www.scentstrategy.com

Guide to Designing Bend Reliefs in Sheet Metal Sheet Metal Bend Tips the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. in this comprehensive guide, we delve into the intricate processes of sheet metal. Sheet Metal Bend Tips.

From eziil.com

Sheet Metal Bend Radius Full Guide Chart Sheet Metal Bend Tips in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they have in industries ranging from automotive to aerospace. — imagine bending sheet metal without leaving a single mark or scratch. the basic bending design guidelines that a designer needs to consider when. Sheet Metal Bend Tips.

From dxonedjte.blob.core.windows.net

Sheet Metal Bending Tips at Betty Stephenson blog Sheet Metal Bend Tips — how to design bend reliefs & corner reliefs for sheet metal parts. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle.. Sheet Metal Bend Tips.

From www.mac-tech.com

7 Tips for Bending Long Pieces of Sheet Metal Sheet Metal Bend Tips sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include wall thickness, bend radii, and bend allowance. Sheet metal parts are usually fabricated from a. Sheet Metal Bend Tips.

From www.rapiddirect.com

What Is Sheet Metal Bending? Basics, Allowance, and Tips RapidDirect Sheet Metal Bend Tips — sheet metal design tips for bending. sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle. in this comprehensive guide, we delve into the intricate processes of sheet metal bending, the vital role of press brakes, and the transformative impact they. Sheet Metal Bend Tips.

From www.komaspec.com

An Engineers’ Guide to Sheet Metal Bending & Laser Cutting Komaspec Sheet Metal Bend Tips — sheet metal design tips for bending. — imagine bending sheet metal without leaving a single mark or scratch. Sheet metal parts are usually fabricated from a single sheet of metal, so they should have a uniform wall thickness. the basic bending design guidelines that a designer needs to consider when modelling a sheet metal component include. Sheet Metal Bend Tips.